About Us

Dreampell today has a 1200 square metre factory with in-house production, divided into departments: product development and modelling, cutting, preparation, assembly, re-finishing and testing for quality control of the final product with the customer.

History

2001

Passion

Dreampell

Our company today: partners and headquarters

Dreampell today has a 1200 square metre factory with in-house production, divided into departments: product development and modelling, cutting, preparation, assembly, re-finishing and testing for quality control of the final product with the customer.

A company that looks to the future, capable of anticipating market developments and which, thanks to its three partners Lorenzo Fallani, Matteo Rutilensi and Francesco Cammelli, responds to the current needs of fashion designers who are increasingly looking for a first-class total supply concentrated in a single external partner.

The company’s main strong points are its continuous investments in improving the professionalism of its human resources and technological level of processing, with the aim of increasingly optimising the company’s production capacity.

In recent years, because of market requirements, Dreampell has been specialising in special stitching and embroidery using state-of-the-art automatic machines.

Dreampell’s internal organisation and division of roles is a plus for customers, with all three partners sharing skills, sector strategies and productivity.

Together they have created a company based on craftsmanship, passion and Italian-made products.

Lorenzo Fallani

"In 2001 Matteo Rutilensi and I started a workshop for the cutting and preparation of portfolios for third parties. A few days after our company opened - on 11 September - the world came to a standstill. Despite our initial fears, we remained focused on our work. After only a few months in business, we had the great opportunity to work directly for The Bridge, the well-known leather goods company in Scandicci. In March 2002 a third partner joined us: Francesco Cammelli, who ran his own workshop assembling wallets. With the arrival of Francesco, Dreampell has evolved further to become a company capable of making the entire product: from cutting to packaging. Our perseverance has paid off and Dreampell has become what it is today - a leading company in the industry. My role is to take care of customer relations and the organisation of the production cycle."

Matteo Rutilensi

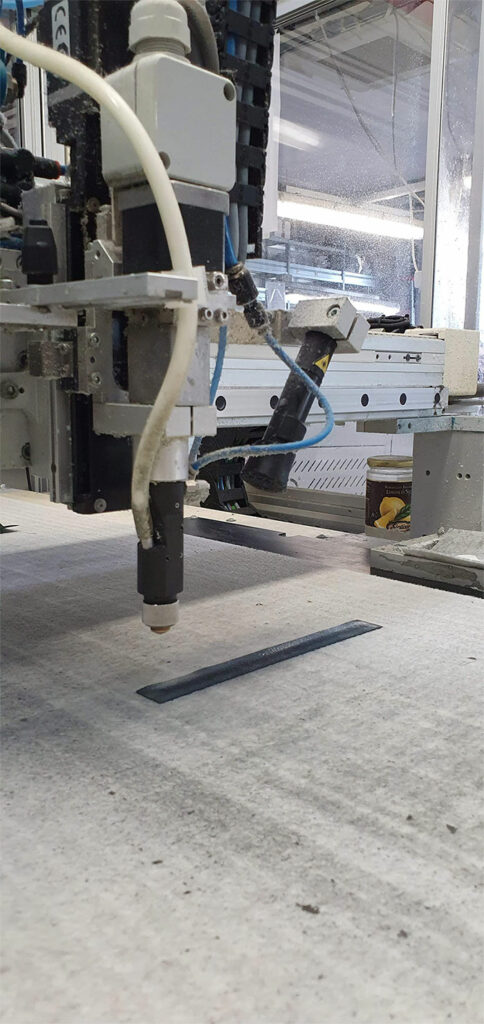

"Dreampell has perfected all types of small leather goods processing step by step, which has enabled the company to establish profitable and long-lasting partnerships with the most renowned fashion brands. The company is divided into four departments: cutting, preparation, assembly and refinishing, in addition to the inspection rooms to check the product's quality with the customer. One of our greatest strengths: continuous investment in technology. I am in charge of cutting, in which we work with three state-of-the-art electronic cutting machines and a latest generation Nesting Table and we cut the leather for everything we produce."

Francesco Cammelli

"Since I have the longest experience, I carry out the quality control of the product and the assembly of the wallets. If necessary, we also produce the samples requested by the customer. The typology of workmanship that has distinguished us for many years is what is called the rib work, which is renowned for its difficulty. There is a department entirely dedicated to this, equipped with ovens for drying and machines for colouring the pieces. We produce an average of 15,000 portfolios per month, and the company can manage even more. Our aim is to maximise our potential and production capacity."

The value of craftsmanship

and training

When it comes to the Made in Italy label in the world, people immediately think of luxury fashion and leather goods, which are unquestionably based on the history and identity of the craftsmen in our country.

Dreampell is founded precisely on these solid elements: skill and deeply-rooted tradition.

Producing a piece of Made in Italy leather goods means bringing out the history of Italian craftsmanship, Florence and the knowledge of those tanners who in the 1500s brought to Tuscany the mastery and knowledge of an expertise to be handed down from generation to generation.

The Made in Italy label is in fact one of the most powerful brands in the world and many people ask themselves: how is this possible? Simply because the quality of the finished product is the result of the craftsmanship that carefully follows a high value chain, the result of research, innovation and continuous training of personnel that can only be found, in its entirety, in Italy.

Mission

The Value of the Made in Italy label is

The Value of Florentine Craftsmanship

In this sentence we find the philosophy and mission of Dreampell.

Equality determined by a continuous interaction between the past and the future, between craftsmanship and new technologies, between culture and innovation, a combination that embodies the value of the Italian product, unique and unparalleled in terms of raw materials and high quality production.

Dreampell is all this: craftsmanship and craft value while respecting Italian-made work and production.

A company with a futuristic technological vision

Over the years, Dreampell’s workforce has become increasingly specialised through the division of departments: product development and modelling, cutting, preparation, assembly, refinishing and quality control testing of the final product with the customer.

Constant supervision of the various departments, the quality of the raw materials, and the timing and progress of production ensure that Dreampell is now an industry leader.

Craftsmanship and constant investment in high-tech machinery allow Dreampell to produce at high rates and with excellent quality.

Today, Dreampell is one of the top-tier small leather goods companies with the greatest in-house production potential and is investing in continuously improving the quality of its productivity.

About Us

Dreampell today has a 1200 square metre factory with in-house production, divided into departments: product development and modelling, cutting, preparation, assembly, re-finishing and testing for quality control of the final product with the customer.

History

2001

Passion

Dreampell

Our company today: partners and headquarters

Dreampell today has a 1200 square metre factory with in-house production, divided into departments: product development and modelling, cutting, preparation, assembly, re-finishing and testing for quality control of the final product with the customer.

A company that looks to the future, capable of anticipating market developments and which, thanks to its three partners Lorenzo Fallani, Matteo Rutilensi and Francesco Cammelli, responds to the current needs of fashion designers who are increasingly looking for a first-class total supply concentrated in a single external partner.

The company’s main strong points are its continuous investments in improving the professionalism of its human resources and technological level of processing, with the aim of increasingly optimising the company’s production capacity.

In recent years, because of market requirements, Dreampell has been specialising in special stitching and embroidery using state-of-the-art automatic machines.

Dreampell’s internal organisation and division of roles is a plus for customers, with all three partners sharing skills, sector strategies and productivity.

Together they have created a company based on craftsmanship, passion and Italian-made products.

Lorenzo Fallani

"In 2001 Matteo Rutilensi and I started a workshop for the cutting and preparation of portfolios for third parties. A few days after our company opened - on 11 September - the world came to a standstill. Despite our initial fears, we remained focused on our work. After only a few months in business, we had the great opportunity to work directly for The Bridge, the well-known leather goods company in Scandicci. In March 2002 a third partner joined us: Francesco Cammelli, who ran his own workshop assembling wallets. With the arrival of Francesco, Dreampell has evolved further to become a company capable of making the entire product: from cutting to packaging. Our perseverance has paid off and Dreampell has become what it is today - a leading company in the industry. My role is to take care of customer relations and the organisation of the production cycle."

Matteo Rutilensi

"Dreampell has perfected all types of small leather goods processing step by step, which has enabled the company to establish profitable and long-lasting partnerships with the most renowned fashion brands. The company is divided into four departments: cutting, preparation, assembly and refinishing, in addition to the inspection rooms to check the product's quality with the customer. One of our greatest strengths: continuous investment in technology. I am in charge of cutting, in which we work with three state-of-the-art electronic cutting machines and a latest generation Nesting Table and we cut the leather for everything we produce."

Francesco Cammelli

"Since I have the longest experience, I carry out the quality control of the product and the assembly of the wallets. If necessary, we also produce the samples requested by the customer. The typology of workmanship that has distinguished us for many years is what is called the rib work, which is renowned for its difficulty. There is a department entirely dedicated to this, equipped with ovens for drying and machines for colouring the pieces. We produce an average of 15,000 portfolios per month, and the company can manage even more. Our aim is to maximise our potential and production capacity."

The value of craftsmanship and training

When it comes to the Made in Italy label in the world, people immediately think of luxury fashion and leather goods, which are unquestionably based on the history and identity of the craftsmen in our country.

Dreampell is founded precisely on these solid elements: skill and deeply-rooted tradition.

Producing a piece of Made in Italy leather goods means bringing out the history of Italian craftsmanship, Florence and the knowledge of those tanners who in the 1500s brought to Tuscany the mastery and knowledge of an expertise to be handed down from generation to generation.

The Made in Italy label is in fact one of the most powerful brands in the world and many people ask themselves: how is this possible? Simply because the quality of the finished product is the result of the craftsmanship that carefully follows a high value chain, the result of research, innovation and continuous training of personnel that can only be found, in its entirety, in Italy.

Mission

"The Value of the Made in Italy label is The Value of Florentine Craftsmanship"

In this sentence we find the philosophy and mission of Dreampell.

Equality determined by a continuous interaction between the past and the future, between craftsmanship and new technologies, between culture and innovation, a combination that embodies the value of the Italian product, unique and unparalleled in terms of raw materials and high quality production.

Dreampell is all this: craftsmanship and craft value while respecting Italian-made work and production.

A company with a futuristic technological vision

Over the years, Dreampell’s workforce has become increasingly specialised through the division of departments: product development and modelling, cutting, preparation, assembly, refinishing and quality control testing of the final product with the customer.

Constant supervision of the various departments, the quality of the raw materials, and the timing and progress of production ensure that Dreampell is now an industry leader.

Craftsmanship and constant investment in high-tech machinery allow Dreampell to produce at high rates and with excellent quality.

Today, Dreampell is one of the top-tier small leather goods companies with the greatest in-house production potential and is investing in continuously improving the quality of its productivity.